Microsoft Dynamics 365 for ETO Manufacturing

The Dynamics 365 platform to run your entire ETO Manufacturing business

From engineering to manufacturing to managing the project and product lifecycle and everything in between, we've got you covered.

Projects drive your manufacturing. They should drive your business system too.

What do you manufacture?

Equipment, machinery, electronics, biotech products, engines, pharmaceuticals, planes, trains, ships? If you do it through projects, you are a project business.

For engineer-to-order project and contract manufacturers, projects are the center of your business, but they are not the center of your business system. You need to reorient the way you run your business by make projects the core of your processes and systems so they drive everything.

Connect and manage your entire business from end-to-end with Project Business Automation:

- The project drives your supply chain

- The project drives your production

- The project drives your business

The ETO Manufacturing Project Business Automation Blueprint

The Definitive Guide to the future of business systems for ETO Manufacturing companies. What you will learn:

- The problem PBA solves for ETO and why it is needed

- Core elements of PBA and how they work

- How you can enhance PBA for your ETO company

- The business case for PBA and benefits for each stakeholder

- What PBA means for the future of ETO industries

Project Business Automation is a new approach in solutions for project-driven companies and defines new rules for what your business system should look like. If you manufacture unique and engineered items for your customers, you need this Blueprint to rethink the way you operate and manage your business.

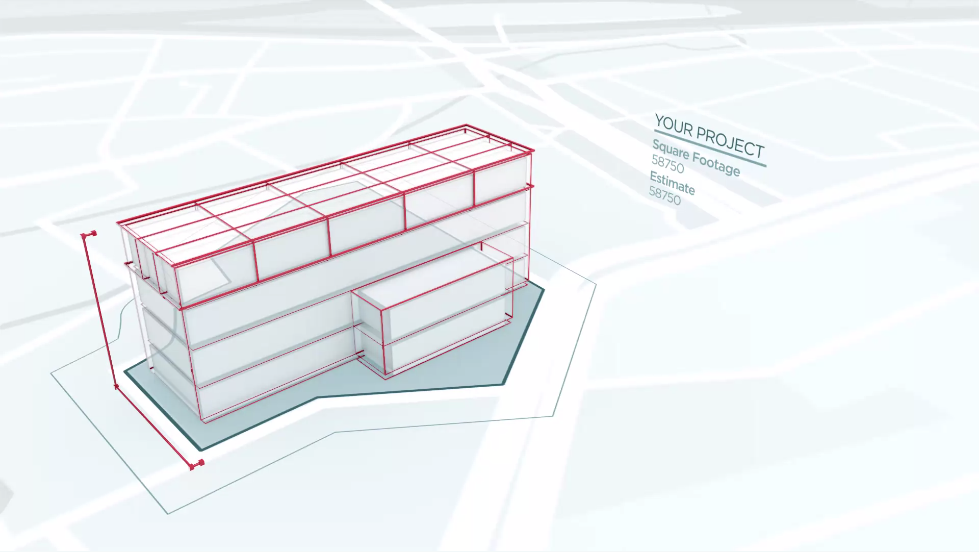

Enhance Sales and Estimation for Your Manufacturing Projects

Build manufacturing projects in minutes instead of hours.

The PBA Project Modeler can take your ETO product and projectize it automatically. Create estimates and project plans in minutes instead of days or hours. Gain speed and control at the same time. Create the right budget and schedule from the start.

- Project estimates are formulated through carefully curated cost models

- Project schedules are constructed through task models that incorporate enterprise best practices

- Enable your estimators and controllers to produce optimal budgets in minimal time and with minimal errors

- Enable project managers and planners to quickly generate project schedules you are confident to keep

Support every ETO business stakeholder

CEO

Gain total control over your business and grow it the right way.

CFO

Manage risk with real-time financial insight of the entire business.

COO / PMO

Go from reactive to proactive management of your projects.

CIO / CTO

Drive real business value with cloud-enabled digital transformation for project business.

Engineer

Integrate engineering project processes from beginning to end.

Client

Build trust with customers through real-time collaboration.

Experience the value of one platform

Take back control

Inter-departmental process and project integration and real-time insight enables you to manage your business proactively instead of reacting after it is too late.

Make data-driven decisions

Working from one source of truth in real time gives you the ability to make informed and timely business decisions instead of guessing at business needs.

Integrate your capabilities

Everything for your ETO manufacturing business on one platform

PLM

- CAD integration

- Product data centralization

- Product structure management

- Revision control

- Engineering change management

- Workflow automation

- Product classification

- Multi-site engineering collaboration

Project Management

- WBS management and scheduling

- Resource management

- Budget management

- CBS management and costing

- Month-end process

- Risk and issue management

- Project (demand) driven MRP

- Material constraint management

- Sensor point status (early detection)

- Project performance analytics

ERP

- GL, AR, AP and fixed assets

- Inventory and shop floor management

- Material Requirement Planning (MRP)

- Project accounting

- Service management

CRM

- Sales process management

- Lead tracking

- Opportunity management

- Account and contact management

- Social media tracking

- LinkedIn sales navigator integration

- Outlook integration

- Mobile access

- Dashboards and analytics

Learn more about ADEACA Project Business Automation™

Meet our ETO / project manufacturing customers

Arranta Bio

Arranta Bio is a contract development and manufacturing organization (CDMO) specializing in new therapies for diseases linked to the human microbiome. Arranta is a project-based firm, providing custom live biotherapeutic products for clinical and commercial supply.Z Modular

Z Modular is a project-driven, one-stop shop for modular buildings and services that utilizes a self-bracing structural system that enables more factory completion than other modular construction system. Z Modular helps building developers reduce the cost of design, fabrication and building assembly with fully finished modular buildings.The Jackson Laboratory

The Jackson Laboratory, founded in 1929, is an independent, 501(c)3 nonprofit biomedical research institution based in Bar Harbor, Maine, with a National Cancer Institute-designated Cancer Center and a genomic medicine institute in Farmington, Conn. It employs more than 2,300 staff, and its mission is to discover precise genomic solutions for disease and empower the global biomedical community in the shared quest to improve human health.

ICM

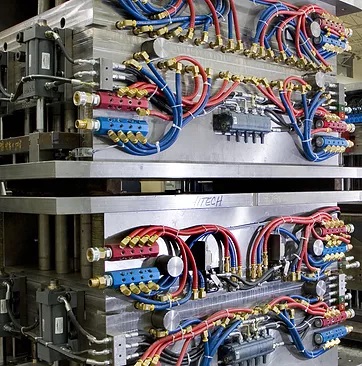

Based in Colwich, KS, ICM, Inc, ICM engineer, build, and support the biofuels industry’s most efficient and innovative ethanol plants. Specializing in ethanol industry engineering and construction, Advanced Gasification Technology, Advanced Oil Recovery™, Selective Milling Technology™, Fiber Separation Technology™, and Gen 1.5 Corn Grain to Cellulosic Ethanol Technology™Hi-Tech Mold & Engineering, Inc

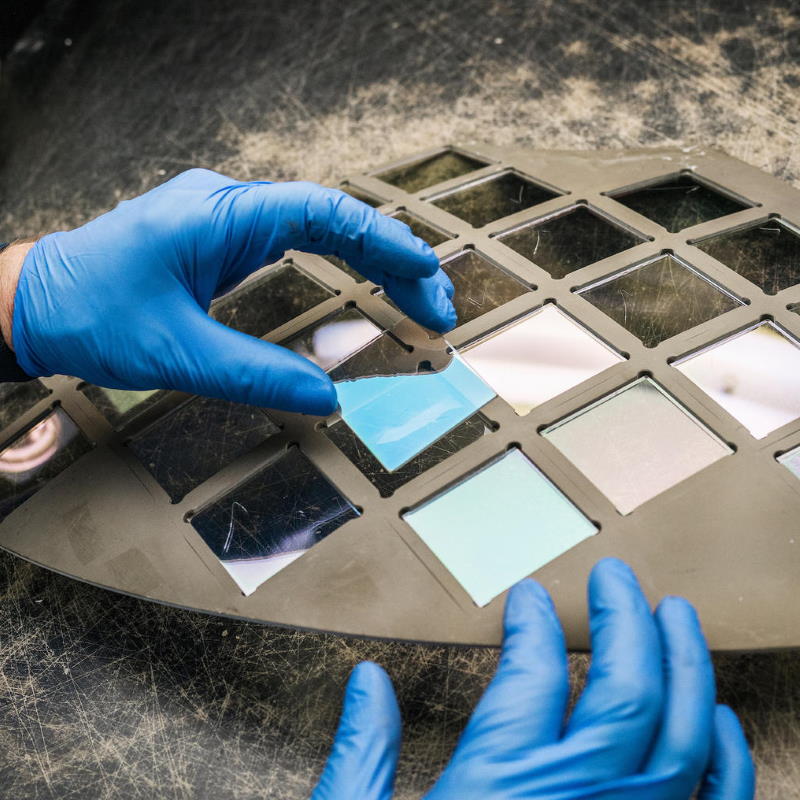

Hi-Tech Mold & Engineering is a full service supplier for the plastics and tooling industries.Qioptiq

Qioptiq designs and manufactures photonic products and solutions that serve a wide range of markets and applications in the areas of medicine, life science, industrial manufacturing, defense and aerospace, and research and development.

READ THE CASE STUDYWilliams Advanced Engineering

Williams Advanced Engineering is the technology and engineering services business of the Williams Group. The company provides world class technical innovation, engineering, testing and manufacturing services to deliver energy efficient performance to customers.Holland & Holland

Holland & Holland is a distinguished century old British custum gunmaker and clothing retailer based in London, England, which offers handmade sporting rifles and shotguns. The company holds two royal warrants.Kailis Marine

Kailis Marine is part of the MG Kailis Group, one of Australia’s most trusted and respected marine organisations. Kailis Marine offers an integrated service including maintenance, re-builds, and vessel and crew charter and logistics. Our services are supported by established logistics, experienced ship engineers and tradespeople, specialised equipment and dock-side facilities.Rexmoore

Rex Moore Group, Inc. performs both design/build and bid work for most electrical and low voltage projects. The company's structure is unique in the electrical contracting industry, allowing it to remain competitive on smaller projects while its experience and financial strength enable it to perform projects of any size.Envac

Envac Group invented the vacuum waste system in 1961 and today the systems are in operation all over the world - in residential areas, business premises, town centers, industrial kitchens, hospitals and airports. The system is a part of the city infrastructure, just like electricity, sewage, water supply etc.

READ THE CASE STUDYAPI Group, Inc

APi Group Inc. is a parent company to more than 40 independently managed life safety, energy, specialty construction and infrastructure companies located in over 200 locations worldwide.

READ THE CASE STUDYValley Forge Fabrics

Valley Forge Fabrics, maker of the world’s most innovative textiles and design solutions for the hospitality industry, has been an industry leader for over 40 years.

ETO manufacturing project business content to help you on your journey

Find answers to your questions

Discover more or engage with our project business experts.

PBA Quick Guide

This Quick Guide to Project Business Automation gives you a high-level overview of PBA and how it can be applied to your project-driven business.

PBA Fit Assessment

Quickly find out if Project Business Automation will work for your company. Based on your company's profile, we will share how PBA will solve your problems and bring value to your business.

Send a Message

Simply start an email dialogue to gather some more information about our solutions, our company and our expertise.