I recently reread an article from McKinsey & Co. that I originally discovered last year that discusses productivity within the construction industry. The article posits that ever-larger capital projects are being undertaken, that most of them suffer from cost overruns and missed deadlines, and that better project management and technological innovation can improve the chances of success of those projects. In our case, we have seen these issues get resolved in our own customer base and can corroborate these findings.

1. Projects are getting bigger in size and complexity and there will be more of them

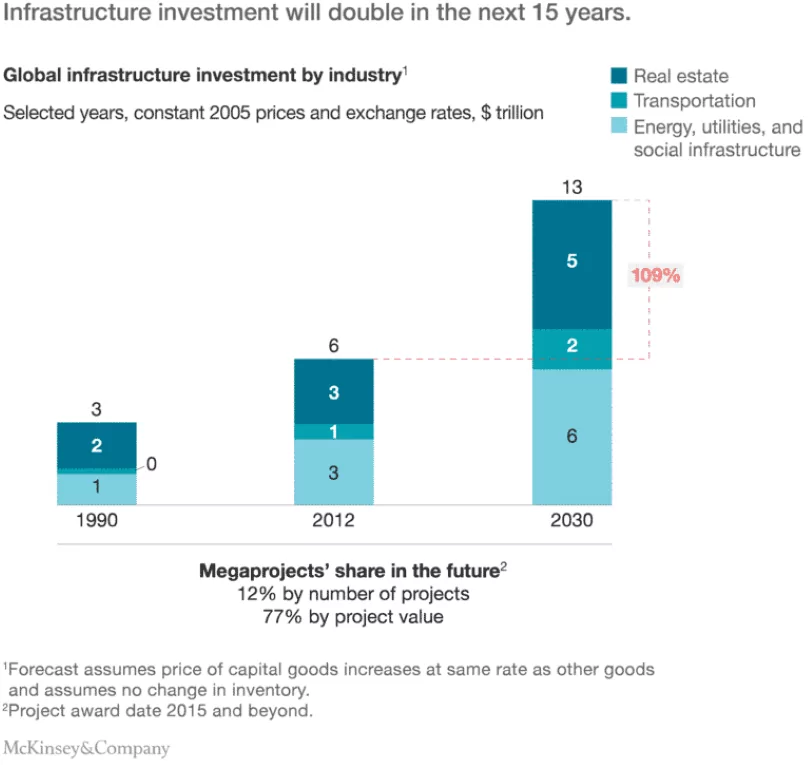

To make the argument that there is a systemic problem that can be addressed, McKinsey cites 3 relevant pieces of data. First, the fact that infrastructure investment will double in the next 15 years, which means managing these projects will be an even bigger struggle. See the figure below.

2. Most projects suffer cost overruns and timeline delays

Second, the construction industry does horribly when it comes to completing projects on time and on budget, pointing to research that estimates that 98 percent of megaprojects suffer cost overruns of more than 30 percent; 77 percent are at least 40 percent late.

3. Productivity is the Key

The main reason McKinsey cites for the poor performance in construction is the lack of productivity as compared to other industries. Productivity has remained stagnant and has even declined in construction, while it has improved in other industries.

Why Lower Productivity?

So why do construction companies suffer from lower productivity? McKinsey argues that it stems from poor project management and lack of technological innovation. In particular, the article notes the following factors accounting for poor productivity and cost overruns.

- Poor organization – decision-making and procurement processes don’t have the necessary speed and scale.

- Inadequate communication – inconsistencies in reporting mean that subcontractors, contractors and owners don’t have a common understanding of how the project is doing in real-time.

- Flawed performance management – unresolved issues stack up because of lack of communication and accountability.

- Contractual misunderstandings – the procurement team typically negotiates dense and complicated contracts. Consequently, if there’s a problem, project managers most likely won’t know how to handle it.

- Missed connections – there are different levels of planning, from high-end preparation to day-by-day programs. Schedulers need to know if the daily work isn’t done, so that they can update the priorities in real-time. However, they often don’t have this information.

- Poor short-term planning – typically companies are good at understanding what needs to happen in the coming two to three months, but they’re not so good at figuring out what has to happen in the next week or two. Because of that, the necessary equipment for the project may not be in place.

- Insufficient risk management – although construction companies pay considerable attention to long-term risks, they really don’t give the same attention to the kinds of risks that crop up on the job.

- Limited talent management – companies defer to familiar people and teams rather than looking to hire the best people for each project.

Over the coming weeks, we will discuss each of these issues in detail. We will reveal some of the underlying reasons why these problems arise, why they are systemic, and what you can do about it.

If your company suffers from cost overruns, missed deadlines and these issues noted above sound familiar, stay tuned as we will also explain how construction companies can improve productivity, better manage their projects and lessen their chances of budget overruns.

> Learn more about the ADEACA Project Business Automation solution for the Construction Industry